ABSTRACT

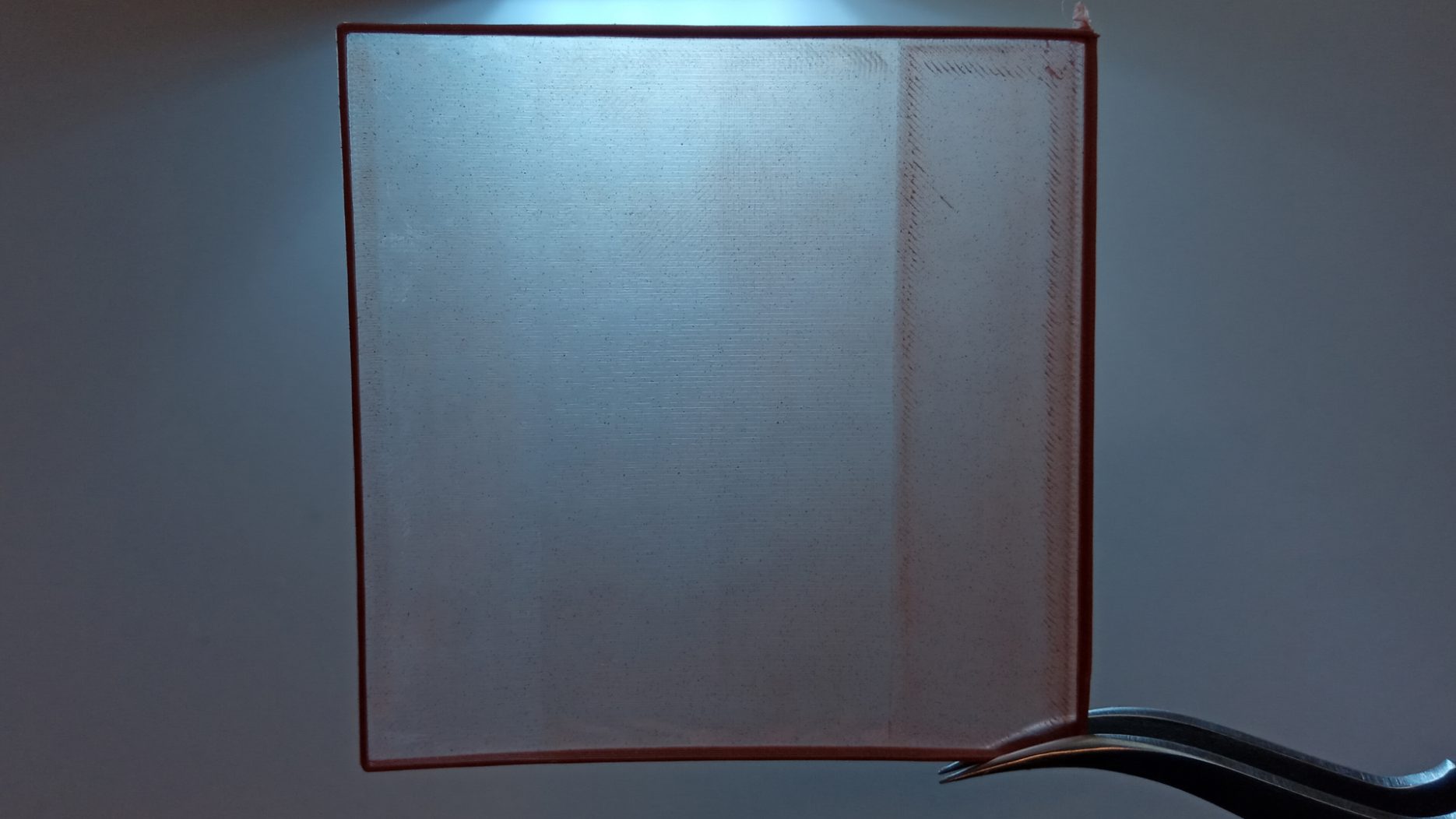

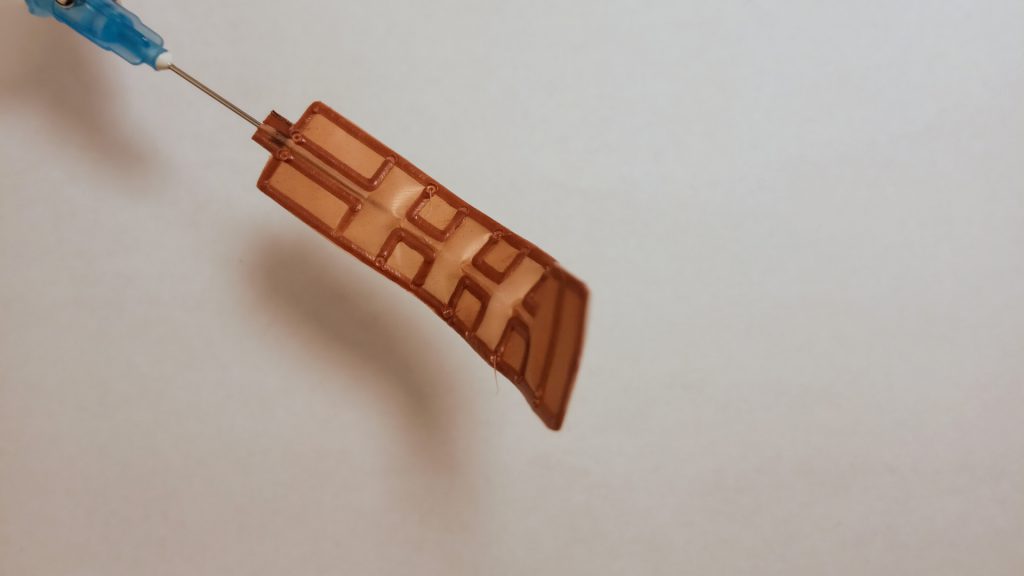

We present QSheet (QuasiSheet), a rapid and cost-effective technique for producing films of variable thickness using unmodified fused deposition modeling (FDM) printers. FDM technology constructs objects by depositing melted filament material layer by layer onto a build platform, which often leads to common print failures such as inadequate layer adhesion and splitting (delamination). The main challenges in developing high-performance films include optimizing printing parameters and workflows to ensure a consistent material flow and uniform mechanical properties throughout the film.

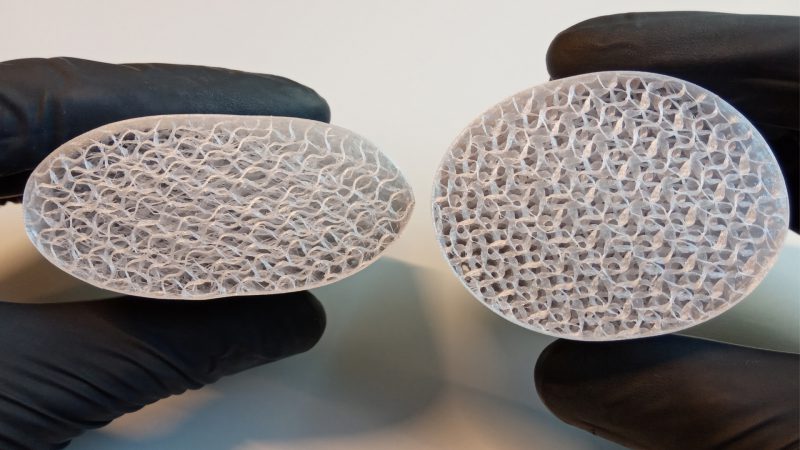

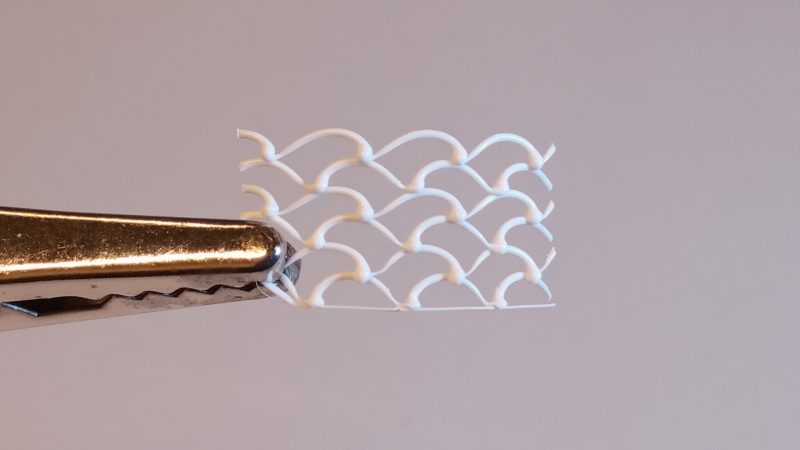

In this paper, we address these challenges by demonstrating two printing techniques: (1) overlapping and (2) overlaying. Both methods significantly reduce the wear and tear of the film, enabling the production of thin, flexible, and durable sheets using standard 3D printing materials. Our work contributes to various applications, including inflatable structures, foldable designs, and soft robotics.

CCS CONCEPTS

- Human-centered computing → Human computer interaction (HCI); Human-centered computing;

KEYWORDS

3D printing, films, sheets, surfaces.

INTRODUCTION

3D printing has significantly impacted manufacturing and prototyping processes. Among the various 3D printing methods, FDM is particularly popular due to its user-friendliness, flexibility, and affordability. While FDM is highly effective for building solid and rigid structures, manufacturing films requires hardware with micron-level accuracy and precise material consistency. This is especially true when attempting to maintain uniform mechanical characteristics (anisotropy), flexibility, and durability across the film. Achieving consistent quality is further complicated by the need for manual bed level corrections and nozzle pressure fluctuations, which can compromise material flow, especially at fine resolutions.

To overcome the inherent technological and material limitations of FDM technology, we propose two techniques: overlapping and overlaying. Overlapping greatly reduces film tearing along the X and Y axes, while overlaying improves layer-to-layer adhesion along the Z axis. Both methods require only a few changes in printing parameters when preparing models in the slicing software (slicers).

By default, the first layer is printed by placing subsequent layers side by side. In contrast, overlapping works by extruding the next layer partially over the previous one. As layers are thin, this fuses them together to create a strong bond. This is done by altering extrusion width parameters in the software. The overlaying technique begins once the entire layer is finished, with the next layer printed at the same Z height as the previous one. This way, entire layers are fused together, and by changing the printing orientation on every other layer, uniform strength (isotropy) is achieved.

QSheet presents the following contributions:

- Provides a detailed analysis of the behavior and durability of thermoplastic-based films.

- Presents versatile and accessible workflows for 3D printing films of any size, shape, thickness, and material.

- Includes a study of the mechanical properties of the films.

- Describes multiple post-processing techniques such as heat-bonding, annealing, and de-pleating.

STAY TUNED!

More information will be posted soon.

Please check back later for updates.

Creative Commons

Attribution-NonCommercial-NoDerivatives 4.0 International