VIDEO MATERIALS | PROJECT FILES | CONTRIBUTE | COLLABORATE

ABSTRACT

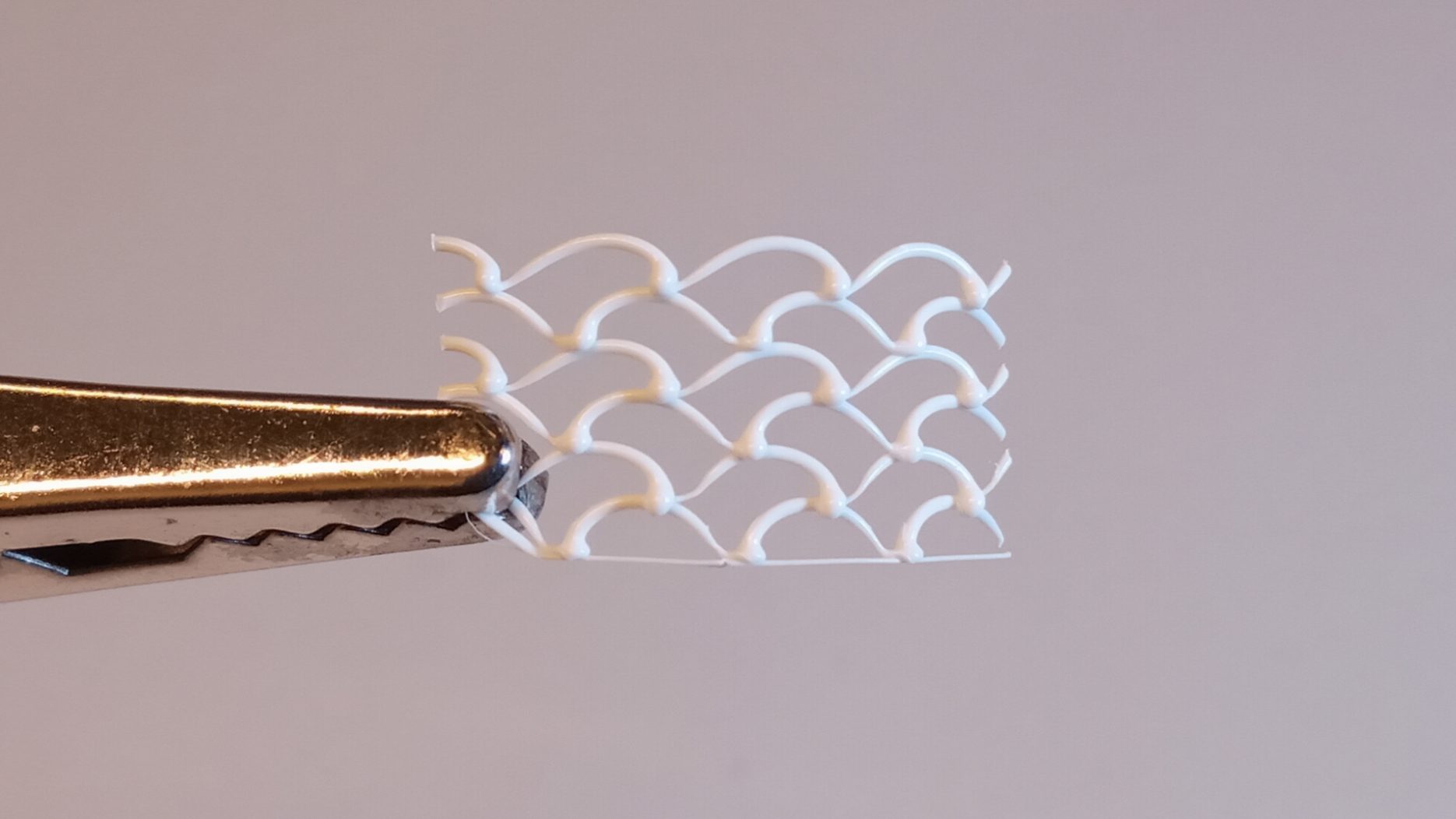

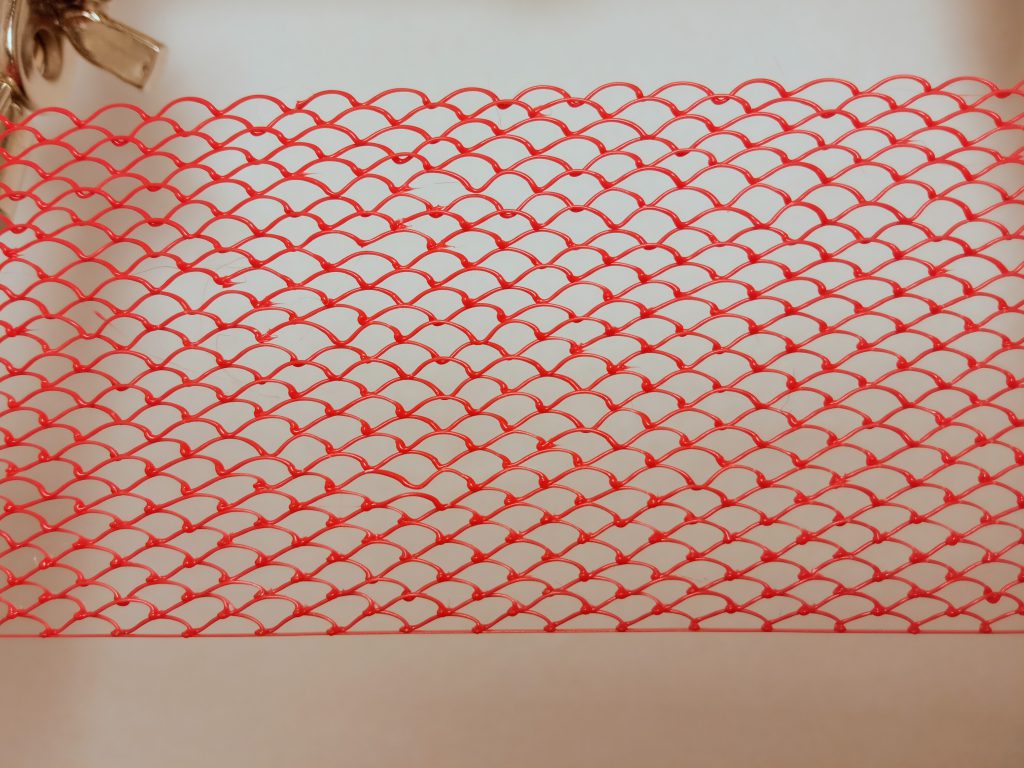

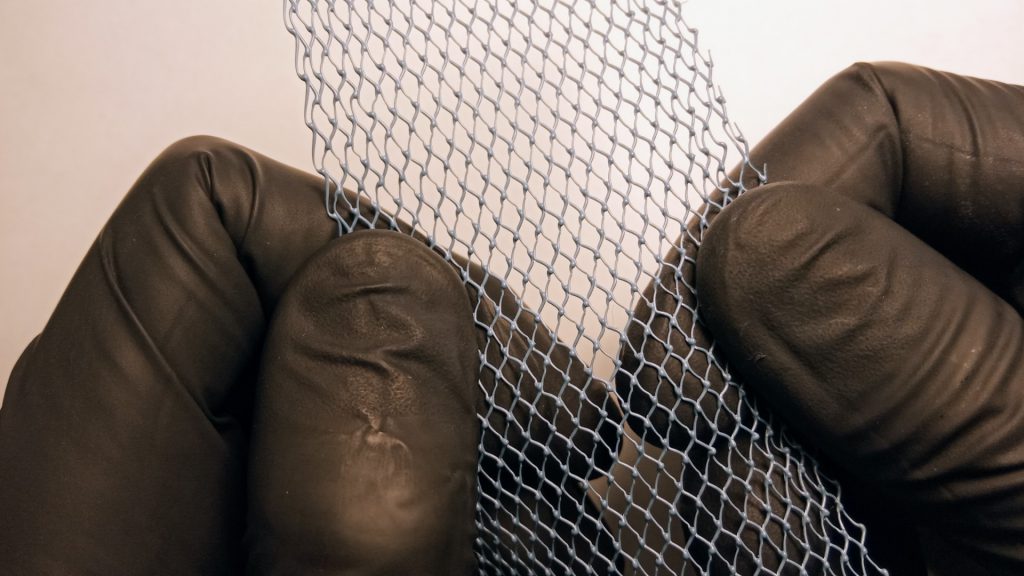

QArc (QuasiArc) are curved-shaped cells designed for manufacturing lattice structures using fused deposition modeling (FDM) technology-based 3D printers. Due to the complex design of lattices, FDM lacks certain features compared to other technologies, making it challenging to produce such objects. Poor layer adhesion, planar printing, and lack of uniform strength (anisotropy) are the main roadblocks that need to be addressed.

To overcome these challenges, an all-new cell design has been developed. The following steps were undertaken to achieve this: (1) designing a network of tiny blocks, (2) chaining them together through simulated non-planar printing (Z-hop), and (3) modifying G-code to extrude material as needed. This new workflow provides valuable insights into the behavior of thermoplastic materials in complex geometric structures.

CCS CONCEPTS

- Human-centered computing → Human computer interaction (HCI); Human-centered computing;

KEYWORDS

3D printing, lattice, cell.

INTRODUCTION

While FDM is one of the most widely used 3D printing technologies due to its cost-effectiveness and ease of use, it faces significant challenges when it comes to manufacturing complex lattice structures. These structures, known for their high strength-to-weight ratios, require precise and robust printing techniques that FDM technology lacks. Primarily, the technology relies on the deposition of hot, liquid material on a planar surface, layer by layer. Therefore, the lack of proper layer-to-layer adhesion and uniform strength is a significant issue. As a result, the go-to technologies for making lattice structures are stereolithography (SLA), selective laser sintering (SLS), and direct metal laser sintering (DMLS).

To utilize FDM technology in such a geometrically complex field, a new type of lattice cell must be developed to overcome these inherent limitations. Thus, arc-shaped cells were designed, making it possible to extrude material not only in the X and Y axes but also in the Z axis. Being far less complex than currently developed cells, this design is a first step in reintroducing FDM technology as a viable alternative to current go-to technologies.

Our approach consists of two parts: design process and slicing. During the design process, a network of tiny blocks is created in computer-aided design (CAD) software, where the distance between two blocks defines the arc width. Afterward, the slicing process takes place using slicing software (slicers). During this process, the arc height is set by the maximum ramping lift and slope angle parameters before enabling the travel ramping lift option. Finally, adjustments to the G-code are made to extrude the material from the start point of the arc, during the travel, and at the end point of the arc. This workflow allows full control of the arc’s height, width, and thickness.

QArc presents the following contributions:

- Provides a detailed analysis of the behavior and durability of thermoplastic-based lattice cells.

- Presents versatile and accessible workflows for 3D printing arcs of any size, shape, thickness and material.

- Includes a study of the mechanical properties of cells printed from various materials.

STAY TUNED!

More information will be posted soon.

Please check back later for updates.

Creative Commons

Attribution-NonCommercial-NoDerivatives 4.0 International